Dear partners and customers, we would like to draw your attention to the fact that we offer rebar cutting and bending machines for 220 V: power and convenience for any conditions.

Machines for bending and cutting reinforcing iron are indispensable equipment at the construction site. But most of these devices require connection to a three-phase network (380 V), which creates difficulties in conditions of small objects or private construction.

An alternative - machines operating from a standard household network 220 V. This is a compact, powerful and convenient equipment that solves the tasks of bending and cutting rebar without the need for complex wiring.

Advantages of 220 V machines

1. Versatility of connection. Such machines can work from any standard outlet available at almost any site, including private construction sites, suburban areas and small construction sites.

2. Compactness and mobility. 220V machines are typically lighter and more compact than their 380V counterparts, making them easier to transport and install. This makes them ideal for smaller construction sites.

3. Еnergy saving. Equipment powered by 220V typically consumes less electricity, which reduces operating costs.

4. Reliability and power. Despite working from the household network, modern models of machines for cutting and bending rebar have high productivity. They are able to cope with rebar diameter up to 16-24 mm, which is suitable for most construction tasks.

Where are 220V machines used?

1. Private construction. The construction of houses, fences, gazebos, frame structures often requires working with fittings, but there is not always access to a three-phase network. Machines for 220 V become the optimal solution.

2. Small construction companies. For small construction teams, it is important to have equipment that can be easily transported to the site and connected to the available power grid.

3. Repair work. Machines for 220V are ideal for repairing concrete structures, installing stairs, platforms and other tasks.

Possibilities of machines for cutting and bending rebar for 220 V

1. Rebar cutting. Machines are equipped with powerful knives that can easily cope with bars up to 16-24 mm in diameter. Cutting is performed accurately and quickly, which is important for saving time on the construction site.

2. Rebar bending. The devices allow to form rebar elements of various shapes: hooks, loops, U-shaped and other structures. This is especially useful when erecting foundations, stairs or frame structures.

3. Ease of operation. Modern models are characterized by an intuitive interface. Most of them have manual or automatic control, which simplifies the work even for beginners.

4. Overload protection. Equipment for 220 V is equipped with protection systems that prevent breakdowns during intensive use.

How to choose a machines for 220V?

1. The diameter of the rebar to be machined. Make sure the machine supports working with the diameter of rebar used in your facility.

2. Capacity. If you have a large volume of rebar to work with, choose models with high cutting and bending speeds.

3. Mobility. For frequent movement around the site, machines with small size and weight are suitable.

4. Quality of materials and assembly. Reliable models are made of durable materials and have quality certificates.

5. Brand and warranty. Give preference to trusted manufacturers that offer warranty service. SmartMetal Group Plus is an authorized distributor of rebar cutting and bending machines and provides all warranties.

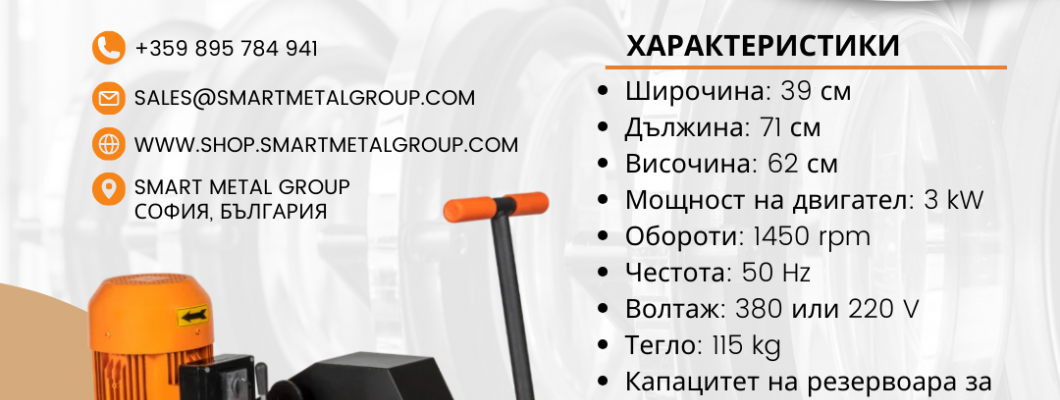

Popular models and their features

Among the popular models of machines for cutting and bending rebar on 220 V can be distinguished:

- Manually operated machines: ideal for small amounts of work, easy to operate.

- Automatic models: allow you to speed up the process and minimize the participation of the operator.

- Combined machines: combine the functions of cutting and bending, which makes them universal (such models are always available on 380V, on 220V on request, depending on the model. 220 volts, 3 phases, 50 Hz-possible; 220 volts, 1 phase, 50 Hz-impossible)

Why choose a machine for 220V?

If you work at a site with limited access to the power grid or plan to perform small construction works, 220V equipment will be an excellent choice. It provides:

- convenience of connection,

- mobility,

- energy and time saving.

Conclusion

Machines for cutting and bending rebar on 220 V -is an ideal solution for those who are looking for compact and reliable equipment for private and small construction. With their help, you will be able to cope with tasks of any complexity without the need to connect to a three-phase network. By choosing such a machine, you get the power of professional equipment with the convenience of domestic use.

Bending machine BT24 , Bending machine MG20B , Cutting machine Power24

-150x150.png)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)