MATRIX 55-S rebar cutting line

MATRIX 55-S enables to maximize customer productivity and save time in cutting operations and eliminate 2-3 manpower using software programming.

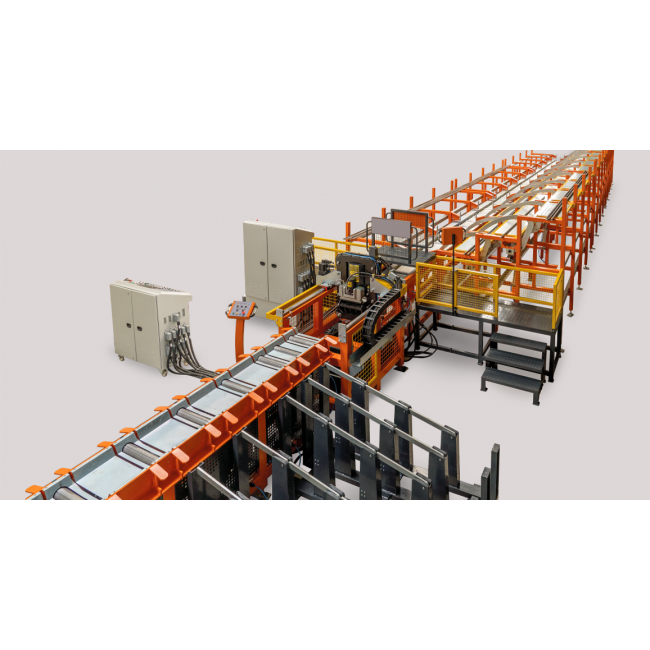

FEEDING CONVEYOR AND FEEDING PLATFORM

• Consists of 12 meters (40 feet) of standard feed conveyor.

OPERATOR PLATFORM - EXTENDED FROM 2 SIDES WITH BRIDGE

• All electrical panels and modules exist in this bridge.

• GMS uses all branded models for electrical components and is easily sourced from local markets.

DIGITAL PANEL

10.1 A touch screen will also be used in the digital panel of both machines.

All machine functions can be controlled both fully automatically and manually. An operator can handle these problems.

PLC screen Windows based systems are used in digital panel.

Remote control is available to connect if something happens to the machine

All required cuts and rebar quantity requirements can be calculated and measured automatically from this digital screen

A barcode system is also available on the Matrix55S Shearline upon request. Instant scanning is also available in Barcode System.

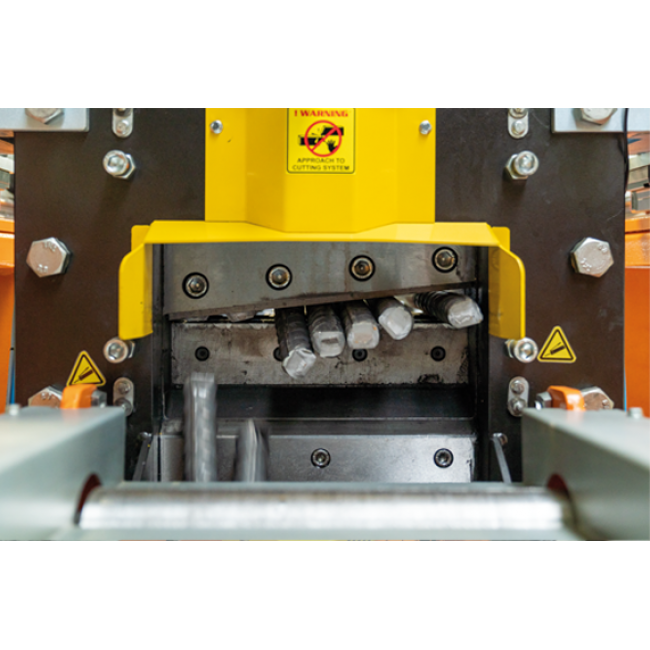

MAIN HYDRAULIC BODY AND CUTTING BLOCK

• All required cutout sizes will be organized by hydraulic system and detailed cutting requests organized by servo systems. All necessary small and large sizes are organized with servo control systems. The movement is hydraulic. The servo system is also used in the Matrix55S.

• Sensitive measuring and cutting is enabled with this unit with the support of a movable main cutting body. (Can move 1 meter forward and backward.)

• The mentality of the cutting and pressing system works with the help of hydraulics

OUTPUT CONVEYOR AND COLLECTION BINS

Consists of 6 meters (20 feet) 4 collection container pockets on one side and 6 meters (20 feet) 4 collection container pockets on the other side.

The unwinders can be opened automatically using a pneumatic system

Consists of 6 meters (20 feet) 4 pocket collection containers.

All arms can be opened automatically.

The cut rebars can be unloaded automatically to the desired container

Modular main pockets, the length can also be adjusted.

DIAMETER / INCH LAT SIZE | STRENGTH OF STEEL | ||

45 kg/mm2/ pcs | 65 kg/mm2/ pcs | 85 kg/mm2/ pcs | |

Ø 55 / #14 | 1 | 1 | 1 |

Ø 40 / #14 | 5 | 4 | 4 |

Ø 36 / #11 | 6 | 5 | 5 |

Ø 32 / #10 | 7 | 6 | 6 |

Ø 28 / #9 | 8 | 7 | 7 |

Ø 26 / #8 | 11 | 10 | 10 |

Ø 22 / #7 | 13 | 12 | 12 |

Ø 20 / #6 | 14 | 13 | 13 |

Ø 16 / #5 | 18 | 18 | 18 |

Ø 12 / #4 | 24 | 24 | 24 |

Ø 10 / #3 | 30 | 30 | 30 |

Ø 8 / #3 | 35 | 35 | 35 |

TECHNICAL DETAILS

• Hydraulic motor (KW / HP) 7.5KW / 9.38 HP

• Load roller motor 3x1.1KW

• Motor for load rollers 1X0.75KW

• Unloading roller motor 3X1.1KW

• Remote Control (Remote Connection) Available

• Movingstopper Control Motor (KW / HP) 0.75 KW Servo Control / 2 HP

• Cutting system - Hydraulic system

• Electric work system controlled by PLC

• Control panel 10.1" inch digital screen

• Collection bins available (manual)

• Discharge on one side only

• Unloading system - Hydraulic system

• Total power (KW / HP) 15.85 KW / 21.2 HP

• Energy consumption (KWh) 14.65 KWh

• Gross weight (KG / LBS) 5200 KG / 11.46 LBS

• Cutting sensitivity +- 3 mm

• Hydraulic system pressure (BAR / PSI) 250 (bar) / 3625 PSI

More information about a machine

-150x150.png)