SLS12 AUTOMATIC STIRRUP BENDER

Discover the Power of Automated Rebar Bending with SLS12

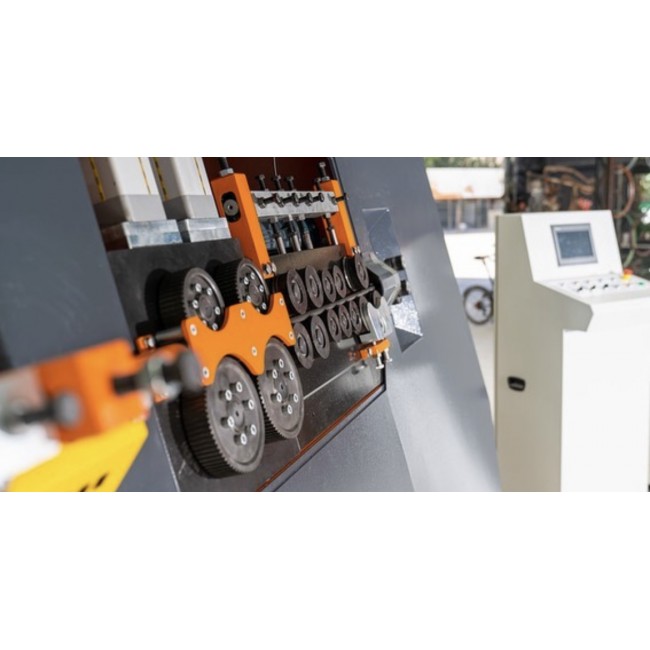

The SLS12 Automatic Stirrup Bender is a next-generation professional machine designed to transform how rebar bending is done in the construction industry. Combining high speed, precision, and reliability, it is the ideal solution for companies seeking optimization, safety, and a competitive edge.

Why Choose the SLS12?

- Up to 2,500 stirrups per hour – Extremely high production capacity for large projects and tight deadlines.

- Dual bar processing – Allows simultaneous bending of two rebars (up to Ø10 mm), increasing productivity.

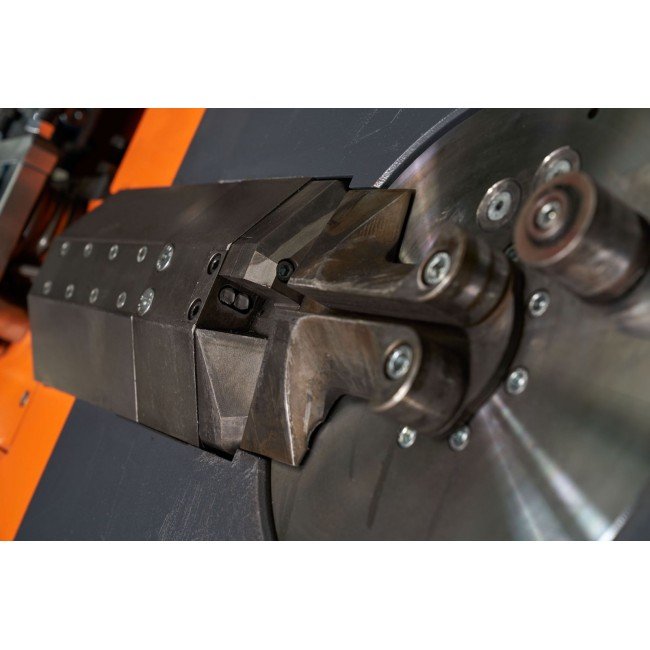

- Precision up to ±1 mm and ±1° – Guarantees accuracy and repeatability, even for complex shapes.

- 100+ customizable shapes – Memory storage for custom figures with fast switching options.

- Low energy consumption – Average power usage of 5 kWh makes it highly economical.

- Durable construction – Components made of high-strength alloy steel for long service life.

- Easy maintenance and fast support – Locally engineered with guaranteed spare parts and responsive service.

Smart Control with GMS Software

The machine features a 15-inch HMI touchscreen panel for intuitive operation. The GMS software is user-friendly and enables quick programming, shape previewing, and automatic error correction. Staff training time is significantly reduced.

Flexible Bending for Any Project

With a bending angle capability of up to ±180°, the SLS12 can produce spiral, square, rectangular, and custom-shaped stirrups—perfect for projects with complex architectural and engineering requirements.

Safe Operation at High Speed

Operator safety is ensured by a built-in three-level emergency stop system, operating pressure of 8–10 Bar, and stable pneumatic drive. The SLS12 is built to work safely and efficiently under heavy workloads.

Energy Efficiency and Sustainability

Thanks to modern servo motors and advanced drive technology, the machine offers an excellent balance of speed and low energy usage, making it both productive and environmentally friendly.

Technical Specifications

| Single strand wire diameter | 6–12 mm / #2–#4 |

| Double strand wire diameter | 6–10 mm / #2–#3 |

| Bending type | 2D |

| Bending capacity | 2x6 mm, 2x8 mm, 2x10 mm, 1x12 mm |

| Drive system | Pneumatic |

| Feeding motor power | SERVO MOTOR 11 kW / 15 HP |

| Feeding speed | 120 m/min / 394 ft/min |

| Bending motor power | SERVO MOTOR 4 kW / 5.5 HP |

| Bending speed | 1250°/second |

| Cutting motor power | AC~ MOTOR 3 kW / 4.02 HP |

| Length tolerance | ±1–2 mm / 0.039–0.078 inches |

| Bending tolerance | ±1° |

| Compressor required | Yes |

| Working pressure | 8–10 Bar / 116–145 PSI |

| Voltage | 380V, 3-phase / 50–60Hz (optional) |

| Gearbox | Industrial type |

| Control panel | 15" HMI display |

| Machine dimensions | 1710 x 5000 x 2340 mm / 67.32 x 197 x 93 in |

| Basket dimensions | 2120 x 2150 x 2300 mm / 84 x 84.64 x 91 in |

| Machine weight | 3000 kg / 6613 lbs |

| Basket weight | 1000 kg / 2204 lbs |

| Languages | English and other language options |

| HS Code | 846229000000 |

Conclusion: A Worthwhile Investment

More than just automation, the SLS12 Automatic Stirrup Bender is a comprehensive solution for your production. With its high performance, energy efficiency, and outstanding precision, it not only reduces costs but also elevates the quality and reputation of your business.

-150x150.png)

-150x150.jpg)

-150x150.jpg)

-150x150.jpg)